-

Phone

86-18121****

-

Address

1102, No. 14, 198, Xinhu Road, Shanghai, China

-

E-mail

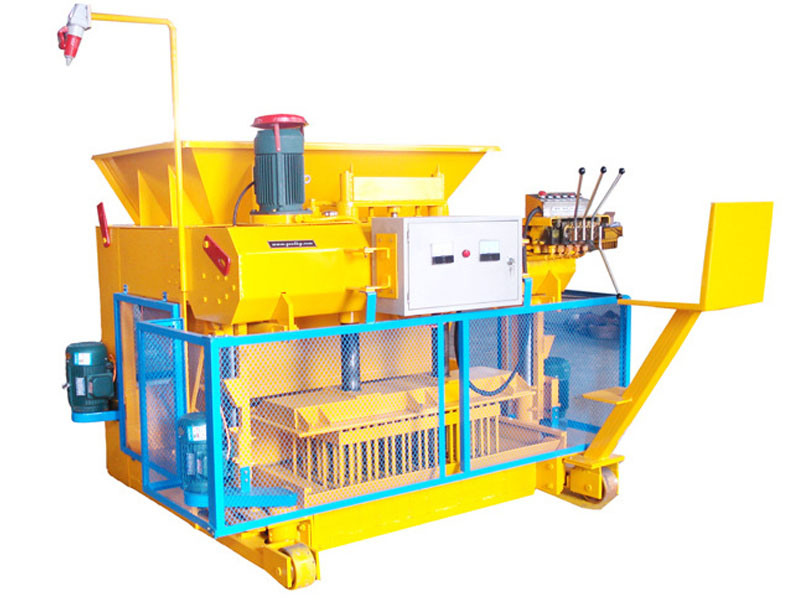

Egg Laying Cement Concrete Block Brick Making Machine

Cement/Concrete Block Making Machine, Block Making Machine, Block Machine

Description

- Model NO.: SAEB6

- Type: Concrete Iron Molding Machinery

- Method: Vacuum Extruder

- Brick Raw Material: Cement

- Tolerance: 0.5mm

- Mould Period: 24s

- Power: Host Machine Power13.45kw

- Transport Package: Naked in Container

- Origin: Jiangsu, China

- Certification: CE, ISO9001: 2000

- Processing: Brick Production Line

- Product: Tile

- Automation: Non Automation

- Condition: New

- Total Machine Power: 22.05kw

- Trademark: Super-above

- Specification: CE

- HS Code: 847480200

SABM-2 Brick making machine line

1.Introduction

1).This machine produce hollow, solid, paving, and interlock bricks/ blocks.

2).Using carburizing technology to increase mould service life.

3).CE, SGS, ISO9001 certificated. Export to 140 countries with high quality and competitive price.

4) Suitable for small and middle investment.

Specifications

mobile block machine

1Electric type

2Twice-vibration of molding core

3No need pallets, cost down

4Easy to operate

1. Introduction

SABM series electric mobile block making machine adopts the advanced technology with smaller power to realize the strong vibration effect. It changes the former one-time-vibration into twice-vibrations of molding core, so the block is made by this machine is in higher density, quicker shaping speed and stronger strength. It has the advantages of good performance, easy movement, saving energy, low investment, convenient operation, etc. By changing moulds, many kinds of blocks can be made. It is the ideal equipment to produce high-quality blocks.

2. Features

ü Mobile type, convenient to move anywhere.

ü No need pallets, reduces investments, and it saves labor to put pallets.

ü Easy to operate.

ü Energy saving. It doesn't need much electricity as stationary type.

ü No chimney to protect the environment and avoid pollution.

3. Parameters

Model |

SABM-12A |

SABM-2B |

Molding Quantity |

12pcs/mould (400*200*200mm) |

10pcs/mould (400*200*200mm) |

Cycle time |

25 s |

25 s |

Capacity |

1700pcs/hour |

1400pcs/hour |

Operation pressure |

16-20Mpa |

16-20Mpa |

Excitation frequencies |

3200 times/min |

3200 times/min |

Vibration mode |

Excitation |

Excitation |

Demolding mode |

Hydraulic |

Hydraulic |

Moving pattern |

Automatically move and Hydraulic Steering |

Automatically move and Hydraulic Steering |

Total power |

17.5KW |

16KW |

Total weight |

5100KGS |

4800KGS |

2.Raw materials of the brick:

Wide range of raw materials could be adopted such as fly ash, coal residue, coal wastes, chemical residue, sand, stone, concent, cement, construction wastes and so on. therefore, it is a new tpye of machine which has the characteristics of energy conservation and environmental protection.

Main Technical Specifications of our Mobile egg laying concrete block making machine price

Molding |

6PCS/mold |

Hydraulic pressure |

6-8MPa |

Frequency |

3500/min |

Productivity |

8000~10000pcs/day |

Hydraulic method |

Mold vibration |

Demold method |

Hydraulic |

Turning method |

Hydraulic |

Total power |

12kw |

Total mass |

2600kg |

Molding cycle |

20s |

Raw Material |

crushed stone, sand, cement, dust and coal fly ash, cinder, slag, gangue, gravel, perlite, and other industrial wastes. |

Total power |

concrete blocks, solid/hollow/cellular masonry products, paving stones with or without face mix, garden and landscaping products, slabs, edgers, kerbstones, grass blocks, slope blocks,interlockingblocks, etc. |

Total mass |

widely used in buildings, road pavers, squares, gardens, landscaping, city constructions, etc. |

Capacity

Item |

Sample |

Size (mm) |

Qty/mould |

Cycle molding |

8 Hours |

Hollow block |

|

390*190*190 |

6 |

20~25s |

8640 pcs |

390*140*190 |

8 |

20~25s |

11500pcs |

||

390*90*190 |

11 |

20~25s |

15840 pcs |

||

Solid block |

|

390*190*190 |

6 |

20~25s |

8640 pcs |