-

Phone

86-18121****

-

Address

1102, No. 14, 198, Xinhu Road, Shanghai, China

-

E-mail

Interlocking Cement Block Making Machine

Cement Block Making Machine, Interlocking Block Making Machine, Block Making Machine

Description

- Model NO.: SAILM

- HS Code: 8474390000

- Certification: SGS, CE, ISO

Product Presentation

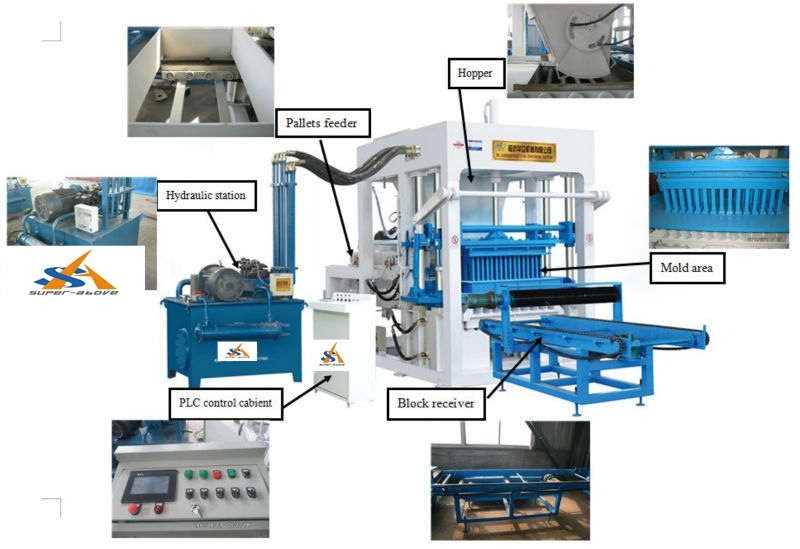

1. SAILM Hydraulic Automatic Brick Making Machinery cal control systems. It is characterized by high efficiency, reasonable design, compact structure, easy operating and convenient maintenance.

2. For the product forming, the machine takes the hydraulic force as the main and the mechanical force as the auxiliary, through vibrating and pressing, to finish the forming procedure. The formed products are high in compressive strength, good in density, perfect in anti-frost and precise in dimensions. Its four guiding columns are coated with cadmium, having perfect torsional strength and wearing capacity. Its material distributor, using sensor and hydraulic proportional driving technologies, can produce forced centrifugal discharging under the function of swing and arc-breaking mechanism to provide quick and even material distributing, and to increase the productivity.

3. For multi-function use

Main Technical Specifications

| Forming pieces | 400*200*200 4pcs/mould hollow brick |

| 240*115*90 12pcs/mould cellular brick | |

| 240*115*53 26pcs/mould standard brick | |

| Total Weight | 6T |

| Forming Cycle | 20-25s |

| Size of host Machine | 3400*2100*2500mm |

| Power of Host Machine | 15kw |

| Exciting Force | 60kn |

| Vibrating Frequency | 3000-4500r.pm |

| Size of Carriage Plate | 900*550*30mm |

| Daily production capacity for hollow bricks | 5800pcs |

| Daily production capacity for cellular bricks | 18000pcs |

| Daily production capacity for standard bricks | 38000pcs |

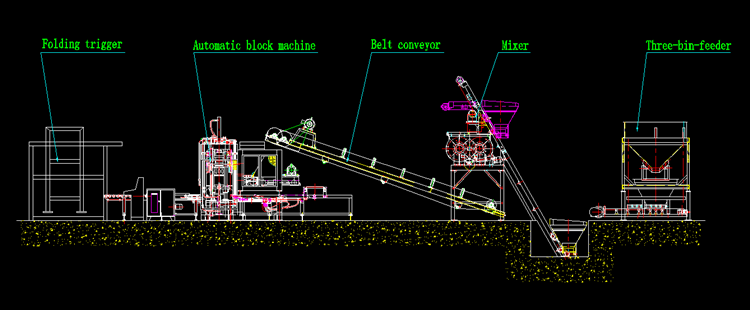

Interlocking Compressed Brick Making Machine, Automatic Cement Block Production Line

Interlocking Compressed Brick Making Machine, Automatic Cement Block Production Line

- Rational design, compact structure, machine body using a high tension steel and special welding technology, widely use import parts, so that the body more stable and reliable.

- Highly efficient, super shock system design, use computer-controlled converter to achieve kinds of vibration frequency and amplitude, thereby increasing the density of products and production effiency greatly.

- All machines adopt the PLC system and controlled by computer that can realize random signal analysis and ensure machines work in the best conditions.

- Equipped with Hydraulic code allocated trigger, can easily make large productivity, automatic production, saving a lot of manpower, maintaining storage yard and liquidity.

- Spiral fabrics semi-mandatory system, so that a more fast uniform material loading.

- Material storage and discharge device adopts enclosed electric roller belt transmission, so that it can control the storage of the small hopper to prevent the concrete liquefied by the effect of vibration ageing technology, and then ensure the product's degree of hardness.

Main Technical Parameters:

Model |

(s) Forming Period |

Pallet Size (mm) |

(kw) Total Power |

Weight (t) |

Size (mm) |

SAILM1 |

12-18 |

1160*880*40 |

72.7 |

13.8 |

7200*2800*2825 |

Theoretical Output

Model |

Name |

Block Size (mm) |

pcs/Pallet |

PCS/h |

PCS/8hours |

SAILM2 |

Block Hollow Brick Standard Brick |

390*190*190 240*115*90 240*115*53 |

10 24 51 |

2400 5760 12240 |

19200 46080 97920 |